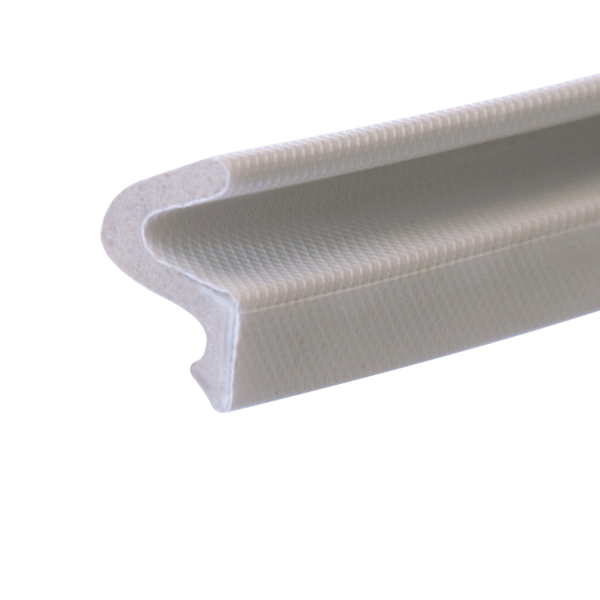

Schlegel QL3009 (AQ21) Aquamac 21 Weatherseal - White

- Designed for rebates 2.7-3.0mm wide

- Polyurethane foam core – high durability, superior recovery performance

- Polyethylene film – weather and UV resistant

- Polypropylene insert – prevents elongation and shrinkage

The Aquamac 21 is a high performance window and door seal by Schlegel. A very effective seal which reduces draughts to a minimum. Aquamac 21 compresses to seal against air and water penetration with excellent memory, returning to its original shape after compression. Non shrinking, even in extreme weather, it is also UV stable.

For nearly 50 years Schlegel Weatherseals have provided durable, colourfast seals against acoustic, air and water filtration. Backed by a ten year guarantee, the Schlegel promise is that Q-Lon is a highly cost effective way of offering continuous high standards of weather sealing, year after year.

- Paint and stain proof

- Embossed exterior, resistant to contamination

- Compatible with cleaning agents

AQ21 is supplied in a continuous piece based on the length ordered, e.g. if you order 2 metres, you'll receive one 2-metre long piece, rather than multiple smaller sections. If you order 9 metres, you'll receive one 9-metre long piece, and so on.

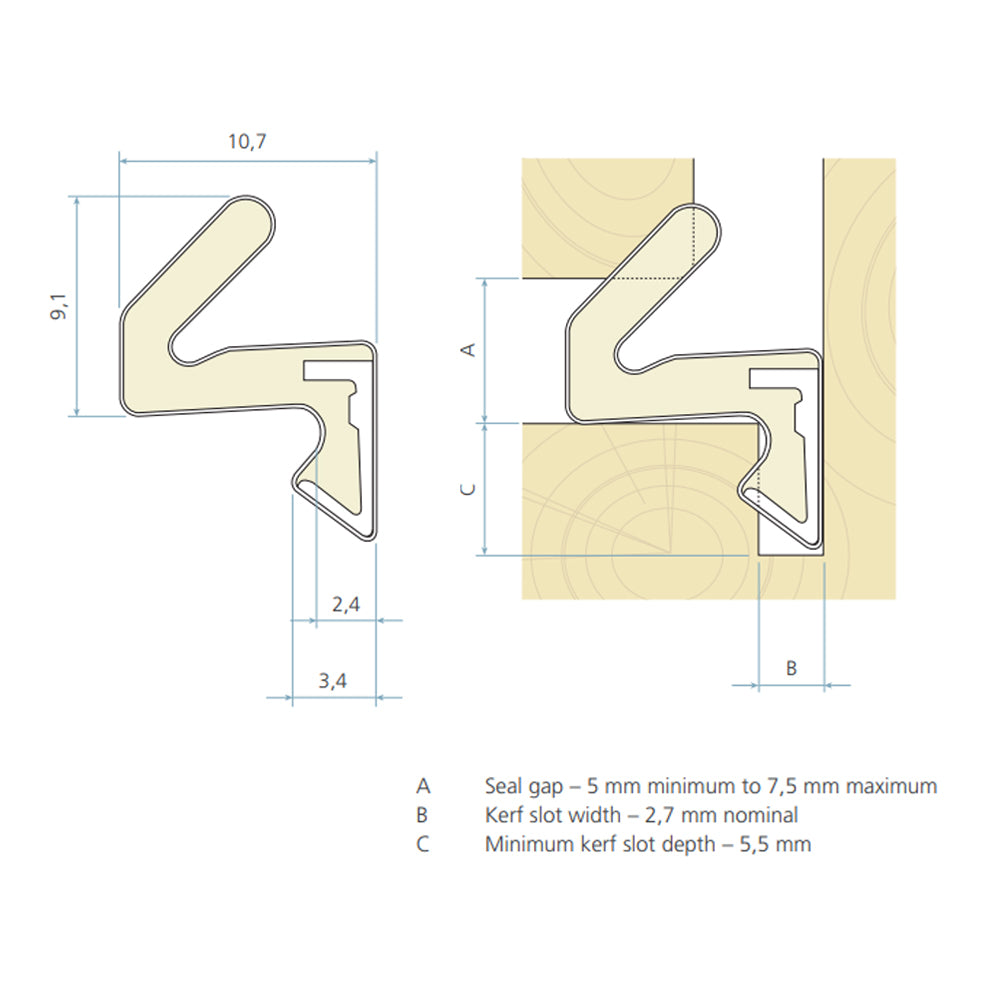

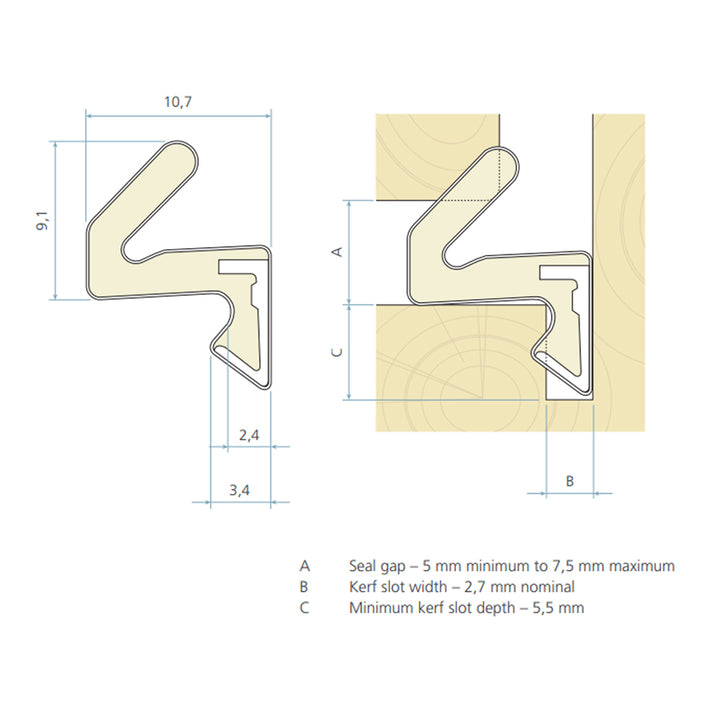

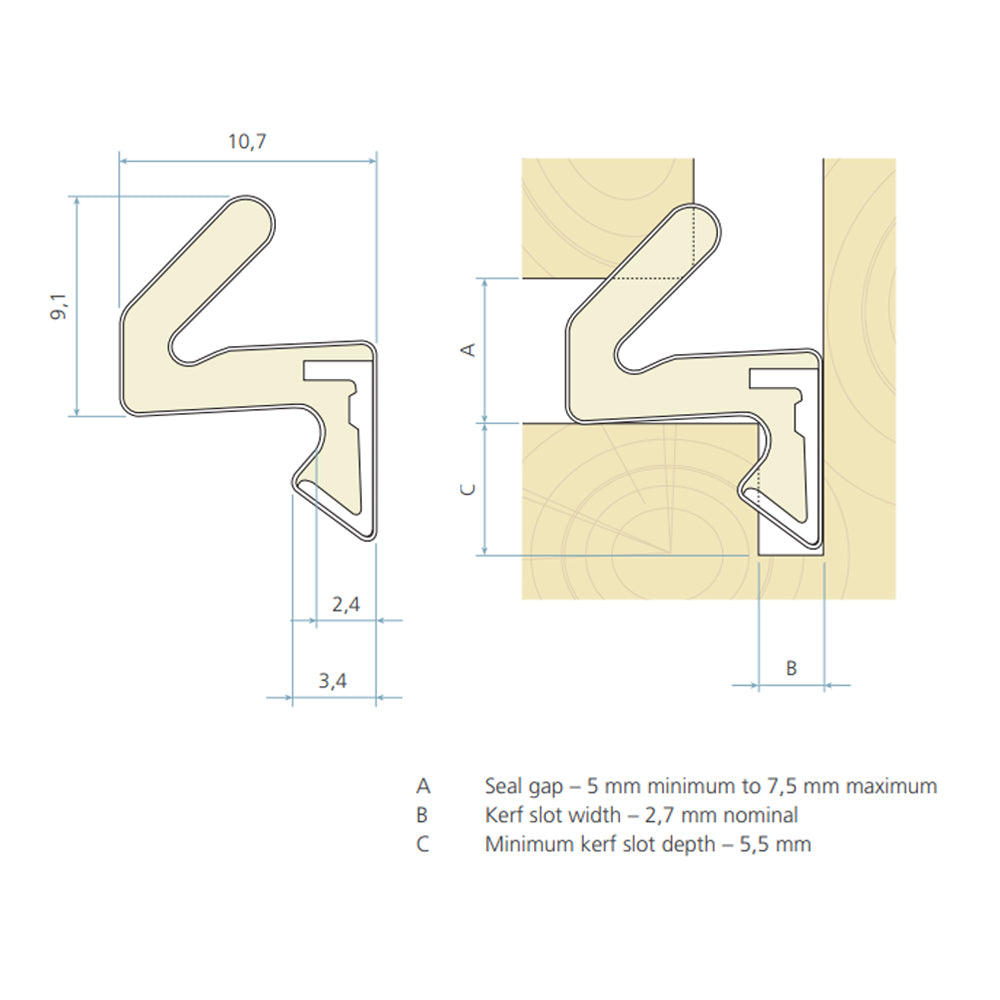

Technical specification

| Main Seal Material | Polyurethane foam |

| Seal Operation | Hinged |

| Seal Application | Windows, Entry Doors, Furniture |

| Seal Fitting Type | Kerf Slot |

| Rebate (mm) | 11.00 |

| Seal gap min (mm) | 4.00 |

| Seal gap max (mm) | 7.50 |

| Groove depth (mm) | 6.00 |

| Groove width min (mm) | 2.70 |

| Groove width max (mm) | 3.00 |

Installation Instructions:

The seal is a simple push fit into the groove and fits alongside the bead or overlap of the window. A roller can be used to roll the seal into the groove to aid insertion. Please make sure not to damage the seal while doing this.

1. Mark the timber beading for cutting. Make sure the “V” of the flipper faces away from the external edge of the window or door (otherwise water can collect in the “V”) and that the top edge is flush to the top of the beading.

2. Determine the gap size and whether the seal is for a rebated fit or flush fit

3. Cut a channel for the foot (see above for groove depth).

4. Measure the size of the seal required and cut to the required length, ensuring

that it is mitred in the corners.

5. Make sure the surface is clean and dry and free from any surface oils, dirt or sawdust etc.

6. Push fit the foot into the routed groove, making sure it is a good tight fit.

7. Make sure the flipper doesn’t fit too proud of the beading otherwise the seal will fail. Similarly, make sure it isn’t lower than the beading otherwise water may collect in the gap.

8. Test the window to make sure there is a smooth opening and closing movement.

You might need...

- Phone support | 0425 229 090

TIP: We always recommend having all materials onsite PRIOR to commencing any restoration project as sometimes delays occur in the courier network which are outside of the control of Lock and Latch.

Installation:

🚚 Shipping & Delivery Information

Please note: We are unable to guarantee any delivery times. If you are in urgent need of your items, please contact us on 0425 229 090. We may be able to arrange an express delivery service, if available.

Local Pick-Up Option: We have a warehouse in Warriewood, Sydney where local pick-up is available. This is by pre-arrangement only. Please contact us to organise a suitable time before visiting.

Important: We always recommend having all materials onsite prior to commencing any restoration project, as delays in the courier network can occur and are outside the control of Lock and Latch.

🌍 International Orders

For international shipping quotes, please contact us on +61 425 229 090.

📦 Estimated Delivery Times

NSW, QLD, VIC

Metro areas: 2–5 business days

Regional & Country areas: 3–14 business days

Western Australia

Perth & Metro areas: Up to 10 business days

Regional areas: 3–14 business days

Public holidays, especially around Christmas, tend to cause delays due to increased volume and reduced working hours. Many courier services experience slower processing times, and there's often a backlog of parcels. Please allow for delays during this time.